Enabling sustainable maritime transport

23/12/2021

Project

Enabling sustainable maritime transport

Background

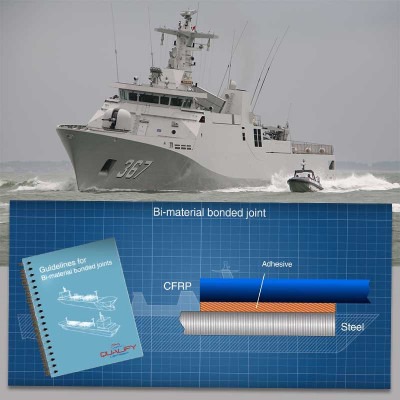

The maritime landscape is facing a wide array of challenges: climate change, call for decarbonisation and an overall need for sustainable operations. One way to reduce fuel consumption is to reduce the weight of the ship, which asks for the development of durable, lightweight solutions that can withstand such loads under extreme conditions, without compromising safety.

The shipbuilding industry has been exploring the use of adhesively bonded composite-to-steel joints in primary structures, but at present misses the certification guidelines to orient the industry when certifying new designs using such hybrid assemblies.

Goal of project

Funded by the INTERREG 2 Seas Mers Zeeën programme, a multi-disciplinary and multi-national team has worked on the QUALIFY project for the past four years to tackle the technological barriers that currently prevent the widespread application of hybrid structures in the industry. The combination of expertise and capabilities from academia, industry and classification societies, and the availability of a unique testing infrastructure, provided optimal conditions to realise the project’s main goals: the formulation of a regulatory framework and a reliable inspection and maintenance technology, enabling incorporation of hybrid joints in future design for ships.

QUALIFY Final Event

The Final QUALIFY event took place on Tuesday, 23 November 2021. The main results and major achievements of the project are also shown in the FINAL QUALIFY movie.

Conclusion

The regulatory framework for the application of hybrid joints in primary structures paves the way towards a more sustainable maritime industry. This lightweight solution realizes a reduction of fuel consumption up to 7% and a considerable decrease of harmful emissions. Furthermore, the hybrid joints enhance ship stability, lead to greater safety during production due to the elimination of hot works and lower the need for maintenance.

The following partners were involved in the project:

- Management & Coordination: Materials innovation institute (NL)

- Academia: Cambridge University (UK), Technical University of Delft (NL), Ghent University (BE)

- Industry: DAMEN (NL), BAE Systems (UK), Parkwind (BE), Com&Sens (BE), Sirris (BE), LM Wind Power (NL)

- Classification societies: Lloyd’s Register (UK), Bureau Veritas (FR)