3DMed

Development and streamlined integration of 3D printing technologies to enable advanced medical treatment and its widespread application

Priority Axis

Technological and Social InnovationSpecific objective

Technological Innovation

Lead partner

Technische Universiteit Delft [TUD]Contact

Begindatum

01/10/2018Einddatum

31/05/2022Project budget

6 843 948 €ERDF amount

4 106 369 €ERDF rate

60%Over

Common challenge

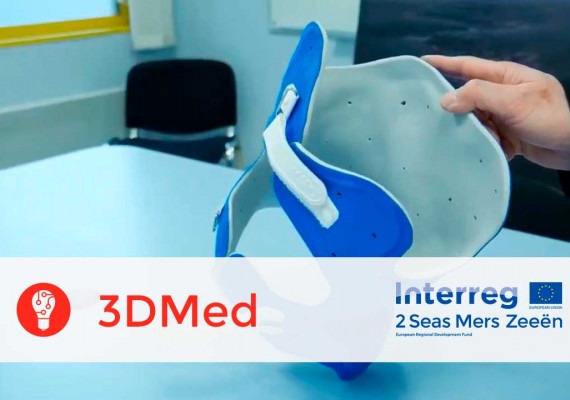

3D printing (3DP) technologies carry the promise of revolutionizing the quality and efficiency of healthcare. However, the required technologies, even when available, were too fragmented to be integrated into routines, affordable and streamlined solutions that can benefit a large number of patients. The challenge for 3DMed was to deliver 3D-printing technologies, enabling a variety of specific benefits. These include : a more efficient use of hospital facilities, reductions to surgeon workload, improved affordability of treatment and better health outcomes for patients.

The 3DMed project worked on patient-specific solutions, personalizing medical devices that are designed using the images acquired for individual patients and best fit their treatment needs. Complexity and miniaturization of the technologies need to be developed to create complex shapes, articulations and miniaturized geometries of implantable medical devices. These instruments have the potential to radically enhance treatment effectiveness and post-treatment recovery. All-in-all this creates more streamlined care, with the ability to integrate diagnosis, design and manufacturing of 3D-printed medical devices into a validated software platform. This is the key to delivering fast and affordable treatments with dramatic life-saving potential.

Overall objective

Main outputs

Cross border approach

Main Achievements

The partnership’s efforts have resulted in the achievement of all set out goals. Protocols, a semi-automated software platform, advanced multi-functional biomaterials, 6 demonstrators and 2 clinical trials have been realized and performed within the project. The lead time for 3D printed personalised medical devices has been shortened from weeks (6-8 weeks) to days (typically < 2 days), corresponding to significant reductions in cost (mostly manpower costs). 31 scientific contributions were made, and two territorial workshops together with a final cross-border event were successfully held.

With the joint efforts of 17 project partners and 14 observer partners, the technology readiness level (TRL) of the 3D printing technology for medical application has been increased from 2-3 to 5-6-7 and integrated into a streamlined, fast, cost-effective software platform for routine clinical use.

Despite the negative impacts of the COVID-19 pandemic, the project was able to streamlining and integrate the various steps of the 3D manufacturing process and integrate the data flows with preplanning

and post-operatory evaluation. It was able to advance the TRL of metallic, composite and polymeric 3D printed medical devices. Additionally, it demonstrated the superior performance and ascertain the clinical benefits of the 3D printed medical devices developed.

This is in addition to the 51 deliverables also achieved during the project’s lifetime. The results obtained from the project were disseminated in different ways. As part of the dissemination effort, in 2021 and the first three months of 2022, 6 newsletters in English, French and Dutch were issued and distributed to the target groups. 31 scientific contributions were made. This included 15 papers were published in specialised scientific journals (see the list in Annexes below), 7 oral presentations were given at specialised European/international conferences, 10 post presentations were given at specialised European/international conferences and 1 PhD thesis.